Today there are more and more proposals for LED light devices for the polymerization of photosensitive materials, but how to understand what they are offering us?

As manufacturers of this type of equipment, we receive requests for clarification on these issues on a daily basis as composite manufacturers specify which frequency ranges are correct for their products but are often imprecise and generic or use incomprehensible terminologies.

UV curing is a light curing process that uses UV energy to

changing a non-crosslinked solids formulation to a crosslinked one.

After the absorption of the UV energy, the photoinitiators produce

free radicals that initiate cross-linking with ligands (monomers

and oligomers) in a polymerization reaction to harden and solidify the material. UV formulations also incorporate various additives such as stabilizers, wetters, adhesion promoters, and pigments to provide desired characteristics or color.

to the cured material.

UV LED light sources efficiently convert 20-40% of the electrical input power into usable UV light without exposure to harmful UV-C or infrared rays. This efficiency translates into approximately 80% energy and thermal savings compared to mercury-based lamps.

From this we can understand that with the same efficacy the declared power on a LED luminaire is much lower than a luminaire equivalent to traditional lamps.

There are two key parameters of an LED lamp that should be understood in order to optimize surface hardening. Identifying these three parameters will result in the best finish, as well as optimal adhesion and surface cure: peak irradiation, energy density and frequency.

The peak irradiance, also called intensity, is the radiant power that reaches a surface per unit area and is measured in W / cm² (power)

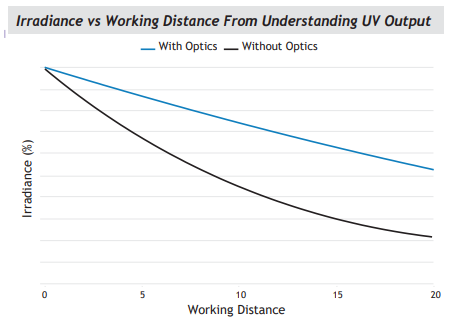

The peak irradiance is affected by the light source output, the use of reflectors or optics to concentrate the rays into a narrower surface impact area, and the distance of the source from the curing surface. The irradiation of UV LEDs on the curing surface decreases rapidly as the distance between the source and the curing surface increases. Fig. 1

Energy density, also called dose or radiant energy density, is the energy that reaches a surface per unit area during a defined period of time (exposure). A square centimeter is again the unit of surface area and the radiant energy density is expressed in units of joules per cmq (J / cm²). Energy density is the integral of irradiance over time. A sufficient amount of energy density is required for complete polymerization.

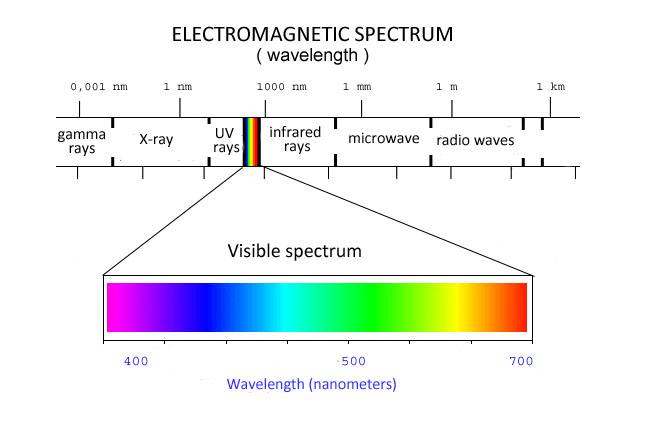

The frequency or wavelength is another fundamental parameter for a successful polymerization and is measured in Nanometers (nm)

Normally the values that are most used are those starting from 380 nm. up to 600 nm.

Each composite or resin manufacturer states on the product packaging how often it must be subjected for good polymerization. It is important to verify that the device you are using for curing can provide the correct frequency.

To better specify, however, it is more correct to speak of frequency range, that is to understand which range of Nanometers our device can cover, therefore to know the range from – to.

For example from 380 to 600 nM. and the more the range is extended, the easier it will be to satisfy the needs of our composite in terms of different polymerization frequencies.

Considerations

UV curing is specifically calibrated for each product. The substrate, formulation and UV energy must be combined / calibrated to maximize yield.

For example, by doubling the thickness of the material from 10 µm to 20 µm the polymerization yield drops drastically, as the photons will have to penetrate twice to polymerize the mass. To overcome this problem we will have to increase the exposure time.

Each wavelength has unique properties and must be paired with the correct photoinitiator to ensure proper cure. Generally a greater

wavelengths of UV light leads to deeper polymerization.

Also, beware of marketing claims, such as “maximum outreach”.

One product may have a higher peak irradiation than another

product, but it could have a drastically reduced energy density.

Key factors for good polymerization:

As you will have understood it is not easy to keep in mind every variable and to obtain a good polymerization. To simplify things a bit, I go on to list the 5 variables that must always be considered by points:

– POWER OF THE LAMPS

It is normally indicated on the label of the device.

– EXPOSURE

This data must be requested from the manufacturer, or at times it can be indicated in the user manual of the appliance.

– FREQUENCY

It is a data that must be indicated in the device manual and usually the range is indicated. This range must obviously cover the values indicated for the product to be polymerized.

– WEATHER

The work cycle time is to be evaluated at the time of processing and must also be chosen taking into account the thickness of the material applied. Normally it is recommended to proceed by layering with thin layers that must be cured individually. Then, once the stratification is finished, a final firing of the completed product is carried out.

– HEAT

The temperature of the chamber in which our product is polymerized must not exceed 45/50 ° C for most of the composites on the market, even if there are materials that require higher temperatures.

Normally this heating of the polymerization area is obtained from the lamps themselves which must be controlled by a microprocessor or more simply by a thermostat.

In many cases this temperature is necessary for a good drying of the product.